Condition: New

Usage: canned food, vegetable, meat, fruit, juice, glass jar, beef, olive, Food industry

Type: autoclave, sterilization pot

Voltage: 380V/220V

Power(W): 15.5Kw

Weight: 1500kgs

Dimension(L*W*H): 4938mm*1600mm*1880mm

Certification: ISO, CE, ASME

Warranty: 1 year

After-sales Service Provided: Engineers available to service machinery overseas

Product Name: Sterilizing retort for pouch food

Quality: high quality

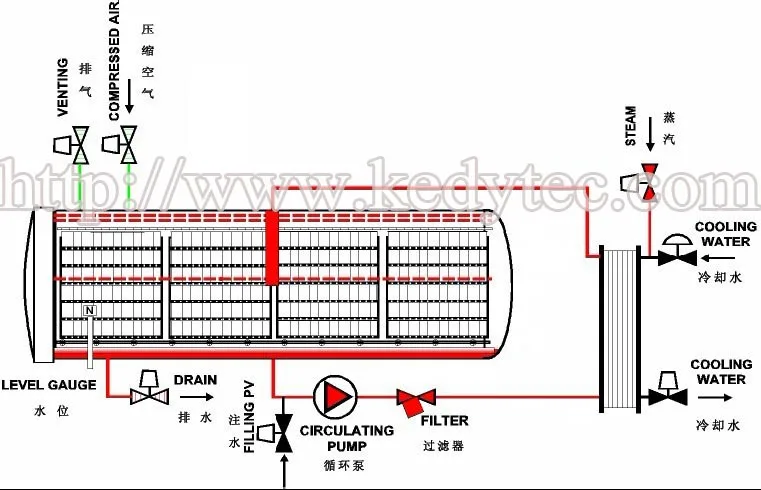

Sterilizing Method: Water spray/Showering type

Category: High pressure high temperature

Material: Stainless Steel 304/316

Advantage: Energy saving, eco-friendly, easy to operate

Price: Cheap

Heating Meathod: Steam boiler/electricity

Control Mode: Full automatic & Semi-auto

Specifications:

sterilizing retort for pouch food

1. stainless steel 304/316

2. high temperature short time sterilization

3. energy efficient, save time and manpower

4. easy to operate and install

5. food industry

Sterilizing Retort For Pouch Food

1. Heated directly, cooled indirectly. The cooling water and process water are not mixed, avoiding the secondary pollution of food.

2. It does not need water sterilizing chemicals and the high temperature can reach the sterilization requirement in a short time.

3. Water steam is discharged directly into the autoclave and used little circulating water, thus saving energy.

4. Different modes of spray for meeting the requirements of different customers.

5. Multiple-step temperature raise and down can preserve the color and flavor of food.

6. Low noise, energy saving, water saving and environment protection.

7. It can save space and labor. It is operated easily.

8. Precise pressure control system can ensure food package won’t change in cooling period, especially inflated packaged food.

9. Computer fully automatic control system

A. Siemens touch screen or Mitsubishi touch screen

B. Non-paper recorder or paper recorder

C. Imported automatic valve

D. Simulation temperature/pressure control system: sterilization temperature (±0.5ºC), pressure (±0.005Mpa)

E. Many sterilization technique in memory for your choice. At most could save 250 sterilization formula.

1. Glass container: glass jar, glass bottle

2. Metal container: tin can

3. Plastic container: PP bottle, HDPE bottle

4. Soft package: Aluminum foil bag, transparent bag, vaccum bag, retort pouches, doy-packs, ect.

Model No. |

Outside Dimension(mm) |

Inner Diameter |

Vessel Length |

Capacity |

Body Thickness |

Max Working Pressure |

Max Working Temperature |

Weight (Kg) |

Installed Power |

Voltage |

||

Length |

Width |

Height |

||||||||||

PLJ.10-1.B.3 |

1885 |

1200 |

1458 |

1000 |

950 |

1.00 |

4 |

0.3 |

147 |

560 |

3.5 |

380 |

PLJ.10-2.B.3 |

2970 |

1200 |

1458 |

1000 |

1900 |

1.80 |

4 |

0.3 |

147 |

650 |

6 |

380 |

PLJ.12-2.B.3 |

3102 |

1500 |

1660 |

1200 |

1900 |

2.60 |

5 |

0.3 |

147 |

860 |

6 |

380 |

PLJ.12-3.B.3 |

4100 |

1500 |

1780 |

1200 |

2870 |

3.70 |

5 |

0.3 |

147 |

1200 |

11.5 |

380 |

PLJ.12-4.B.3 |

4938 |

1500 |

1660 |

1200 |

3820 |

4.80 |

5 |

0.3 |

147 |

1300 |

11.5 |

380 |

PLJ.13-4.B.3 |

4938 |

1600 |

1880 |

1300 |

3820 |

5.70 |

5 |

0.3 |

147 |

1500 |

15.5 |

380 |

Those retort sterilizers in the chart are standard configurations.

We also can customize the retort machine according to your specific requirements or your drawing.

RETORT SYSTEM