Brand Name: OEM Finned Tubular Heater

Model Number: DAF-0134

Place of Origin: Guangdong, China (Mainland)

Condition: New

Type: Air Heater

Power Source: Electric

Dimension(L*W*H): Custom-made

Weight: Based on size

Voltage: 110v-480v

Power(W): 100w-20000w

Certification: UL,CE

Warranty: 1 year

After-sales Service Provided: No overseas service provided

Certificate: ISO,CQC,CSA

Color: Black

Material: SUS304,316,321

Heating wire: Nickel chrome wire

Watt: Customized

Application: Air conditioner, ovens, etc

Shape: I,U,W,etc

Flange: M12, M14, M16, M20, 1’, 1 1/4’, 1 1/2’, 2’

Factory history: Over 21 years finned tubular heater for air heating

Business type: finned tubular heater manufacturer

Straight Electric Finned Tubular Heater Heating Element for Air Duct Heaters

Technique data of Finned Tubular Heater

Sheath Material |

SUS 304/316/ Incoloy 840 |

Spirals |

Nickel - Chrome |

Insulation |

Magnesium Oxide Powder |

Voltage & Watt Supply |

50V-450V & 100W-10KW |

Shape |

U Shape/ W Shape/ I shape |

Resistance Tolerance |

+10% - 5% |

Wattage Tolerance |

+5% - 10% (closer tolerances are available upon special request) |

| Material | Details of contents | Proper environment | Limit service temperature |

| SUS304 | Ni 8.0~10.5 | Air heating | 600°C or less |

| Cr 18.0~20.0 | |||

| Ti ---- | |||

| Mn 2.00MAX | |||

| Mo ---- | |||

| Incoloy 840 | Ni 18.0~22.0 | 800°C or less | |

| Cr 18.0~22.0 | |||

| Ti 0.6MAX | |||

| Mn 1.00MAX | |||

| Mo ---- | |||

| Incoloy 800 | Ni 30.0~35.0 | 260°C or less | |

| Cr 19.0~23.0 | |||

| Ti 0.15~0.6 | |||

| Mn 1.5MAX | |||

| Mo ---- |

Features of Finned Tubular Heater

1. Versatile — Ideal for both comfort and industrial process air applications. Stainless Steel (FTSS) sheath and fin material are available.

2. Fins greatly increase surface area and permit faster heat transfer to the air, resulting in lower element surface temperatures.

3. Construction — Element is constructed like the standard tubular element with the addition of continuous spiral fins (4 - 5 per inch) permanently furnace brazed to the sheath.

4. High Watt Density permits use of fewer elements or higher concentration of installed kW for a given area.

5. Easy Installation — Bending configurations can be designed to fit either round or rectangular ducts. Tight element bends are repressed in hydraulic presses after bending to assure recompaction of refractory material to eliminate hot spots and electrical insulation voids.

6. Power Connections should be made with alloy wire.

7. Over temperature Protection — A high limit temperature cut out is recommended.

8. Bending — Finned tubular elements may be field or factory bent according to the following parameters: I Shape, U Shape and W Shape

9. Special Terminal Construction — Many types of terminals are available to suit different applications.

Applications of Finned Tubular Heater

1. Drying

2. Heat treating

3. Annealing

4. Load banks

5. Curing ovens, dryers, ducts, etc.

6. Microwave oven ranges, panel heaters, baseboards, and heaters

Detailed Images

Certifications

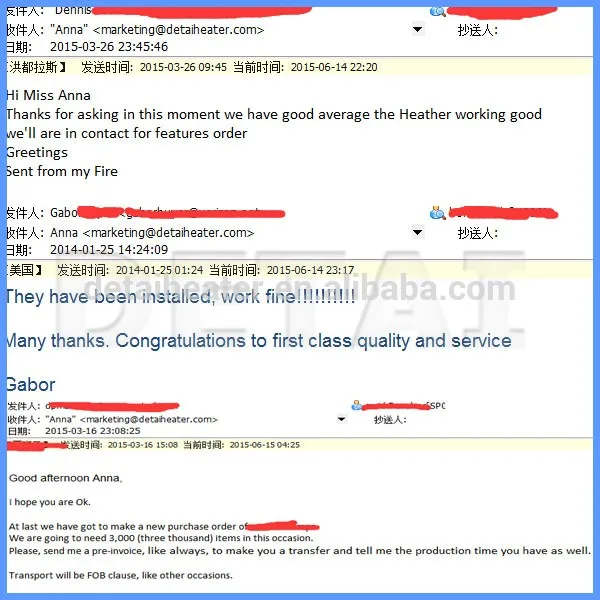

Buyer Feedback

Exhibitions