Brand Name: Henan yuanda steam boiler 4 tons per hour wood log fired

Model Number: DZH series 4ton wood fired steam boiler

Place of Origin: Henan, China (Mainland)

Condition: New

Type: Natural Circulation

Usage: Industrial

Structure: Fire-water tube

Pressure: Low Pressure

Style: Horizontal

Fuel: wood log/fire wood/biomass

Output: Steam

Dimension(L*W*H): customization

Weight: customization

Certification: ISO,IAF,SGS

After-sales Service Provided: Engineers available to service machinery overseas

Color: Customization,such as red,sliver, blue ,green,

Operation style: manual type for this steam boiler 4 tons per hour wood log fired

Advantages: small room space ,low investment

Application field: factory, hospital, school,etc

OEM service: available for this steam boiler 4 tons per hour wood log fired

company type: manufacturer

establishing time: 1956

warranty period: 15 months for this steam boiler 4 tons per hour wood log fired

boiler price: contact kara--0086 186 3827 8138 for the best boiler price!

DZH 4ton 4000kg firewood wood log steam vibrating grate boiler

Some Saturated steam boiler 4 tons per hour wood log fired pictures first :

Boiler's fire grate--good quality wood fired steam boiler:

Manual boiler technical data:

| 4tons wood fired steam boiler | DZH1-1.0 | DZH2-1.25 | DZH4-1.25 | DZH4-1.6 |

| Steam evaporation(t/h) | 1 | 2 | 4 | 4 |

| Working pressure(Mpa) | 1.0 | 1.25 | 1.25 | 1.6 |

| Feeding water temp(°c) | 20 | 20 | 20 | 20 |

| Steam temp(°c) | 184 | 194 | 194 | 204 |

| Hydraulic test(Mpa) | 1.4 | 1.65 | 2.0 | 2.0 |

| Water capacity(m3) | 3.15 | 4.75 | 7.7 | 7.7 |

| Radiation heating area(m²) | 4.8 | 6.34 | 11.81 | 11.81 |

| Smoke blackness(Ringelman ) | ‹1 | |||

| Fire grate area(m²) | 1.3 | 2.55 | 4.72 | 4.72 |

| Delivery weight(t) | 8.6 | 15 | 18.5 | 19.2 |

DZH 4ton 4000kg firewood wood log steam vibrating grate boiler !--DZH boiler series !

Highly praised by the customers overseas !

High cost performace & 100% stable reliablity !

Advantages:

1. Spirally corrugated tube

function: heat transfer enhancement ,1-2 times heat transfer efficiency than before. reduce the spirally corrugated tube numbers,and improve the suppleness to avoid the tube plate cracking

2. Arched tube plate

function : reduce the thermal stress of weld and improve the tube plate suppleness,meantime, simplify the structure

3.Airfoil flue

Function : reduce the smoke temperature of high temperature tube plate,and then reduce the thermal load of boiler bottom.

4.Smook dust separation chamber

Function : reduce the original dust concentration of the steam boiler, and protect environment.

5.Fire-water tube mixed design

Function: optimum structure design ,reduce the boiler size and can save 1/3 building cost of the boiler room.

Burning fuel:

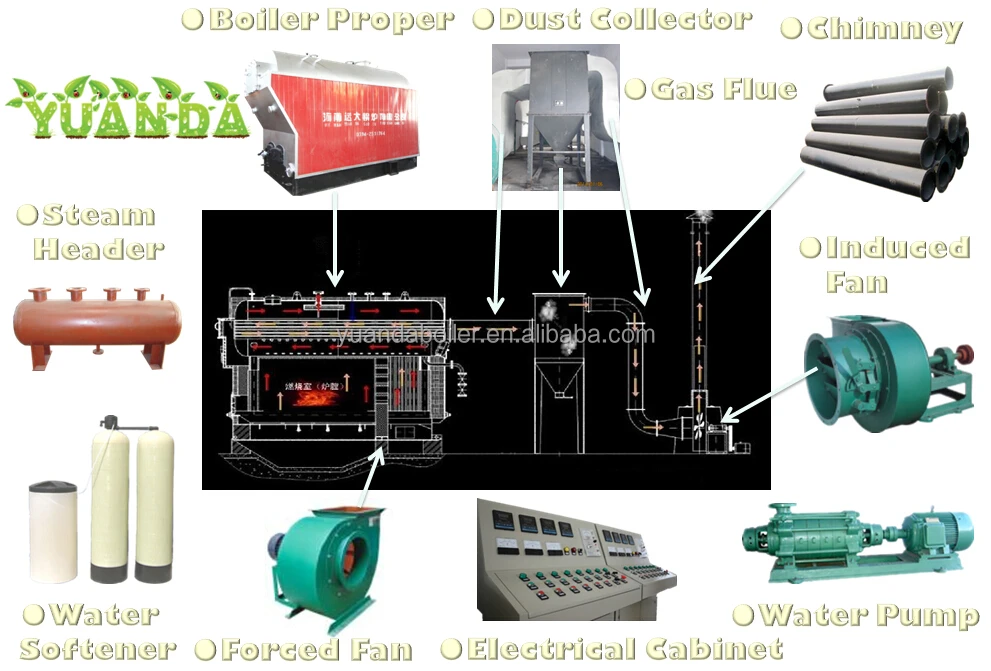

To assure the boiler's high efficiency runnning ,we will confirgure the following auxiliaries /boiler room equipment for our boilers:

For this wood fired steam boiler,whether 1 ton wood boiler,2 ton wood boiler,4 ton wood boiler,we all provide you the following best boiler configuration:

1.wood boiler proper

2.Wood boiler accessories

-FD fan

-ID fan

-Electrical control cabinet

-Valves&instruments

-water pump

-steam header

-chimney

-smoke duct

-Economizer(for improving this wood fired steam boiler's heat efficiency)

-Dust catcher

-Water softener

If you want to change the boiler's total configuration,such as different boiler acessories,we accept OEM service too! As to the detailed accessories pictures,please see the following:

Sincerely welcome to wood boiler price inquiry and factory visiting! We are committed to provide the best boilers in the world!

Contact kara(0086 186 3827 8138 ) for the best boiler configuration!

The following is this wood boiler's brief manufacturing flow chart, from this picture, you could clearly know the wood steam boiler production step, which is first, which is second, but seeing is believing, how about coming to our factory viewing the real production site!

The following picture is one of our Chile 4 ton wood fired steam boiler's running site,2sets of wood fired steam boiler running together for providing continuous and clean saturated steam,we provided the highest quality dry steam and guarantee the steam's excellent quality,just for you!

contact kara--0086 186 3827 8138 for the best boiler price!

Quality Control

1.60 years corporate reputation.

2.X-ray flaw detection.

3.Higher grade welder certificate.

Guarantee and After-sale service

1.two year warranty and full-life service for all our boilers.

2.A full range of original spare parts are available for all yuanda boilers.

3.24 hours technical support by email.

4.Engineers available to service overseas.

Boiler's shippment before arriving at the seaport: